Partner

We warmly welcome the visit of the customers at home and abroad

Recommended products

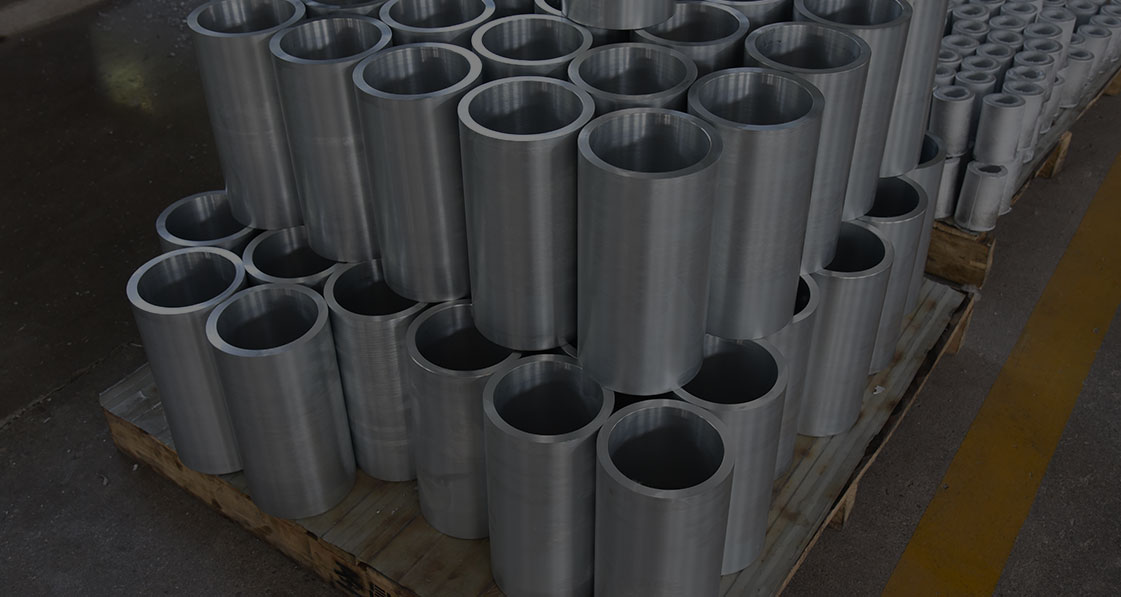

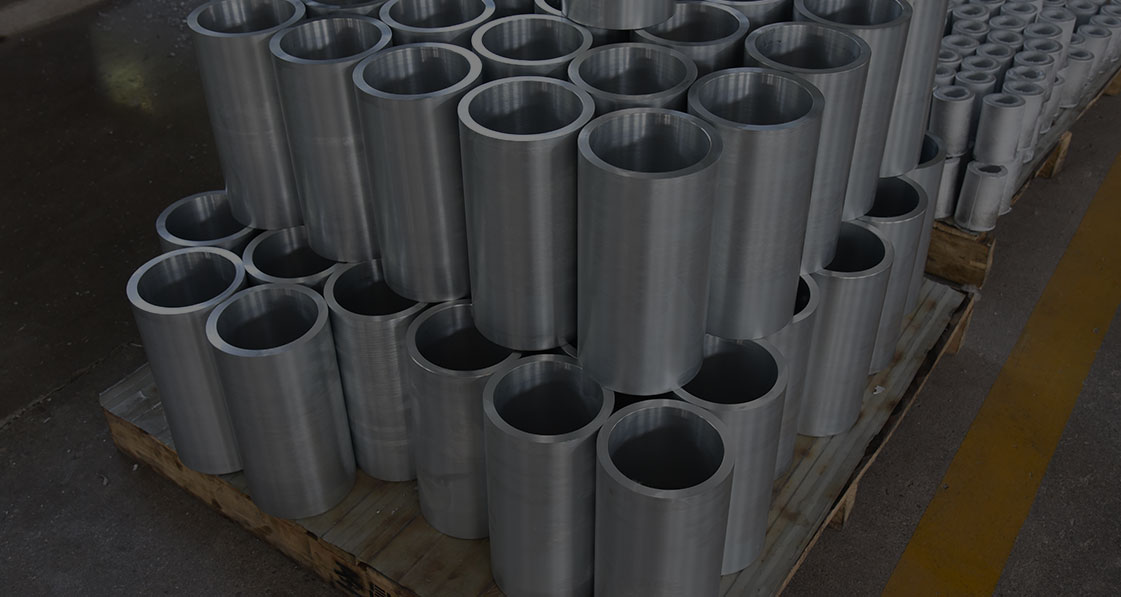

With the wholesale supply, the customized price is affordableSimple production process, low-content alloy, reasonable comprehensive economy; good wear resistance, high hardness, great toughness, weldable, satisfied process performance.

Smooth transmission, satisfied meshing performance, high contact ratio, high gear strength, silence and small vibration. Able to transmit with high power.

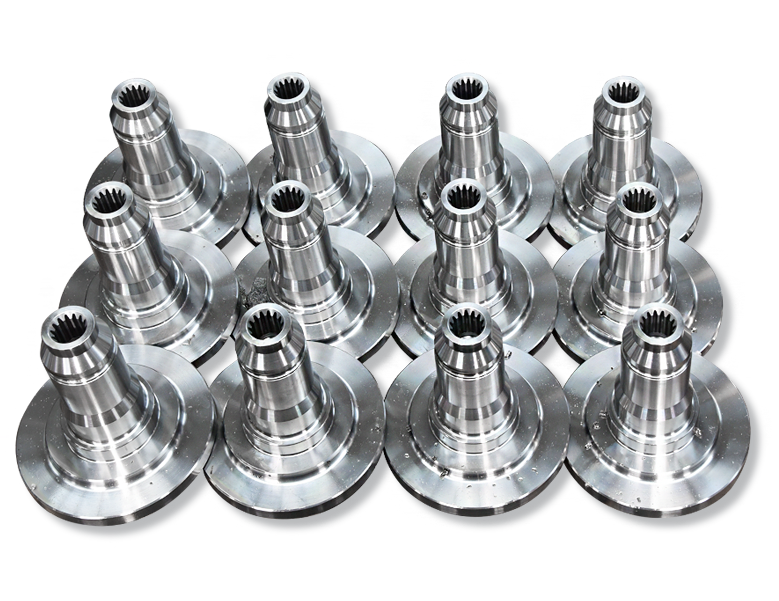

Zn-al alloy, as an excellent and fragile material, has excellent wear reduction and wear resistance, and its wear on grinding parts is smaller than that of copper alloy. The service life of mechanical transmission parts is improved and machining accuracy is maintained.

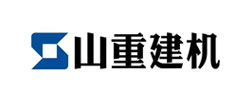

Excellent mechanical performance, stable materials, support the customization based on the drawings and samples. The surface treatment shall be burr-free and the whole is bright.

Bucket teeth

Material: Wear-resisting alloy steel Purpose: Rock or hard ground excavation Read more +Bucket teeth

Material: Wear-resisting alloy steel Purpose: Rock or hard ground excavation Read more +Gear

Smooth transmission and excellent meshing performance.High contact ratio, high gear strength, silence and small vibration. Read more +Gear

Smooth transmission and excellent meshing performance. High contact ratio, high gear strength, silence and small vibration. Read more +Recommended products

With the wholesale supply, the customized price is affordableHigh-quality mechanical precision castings

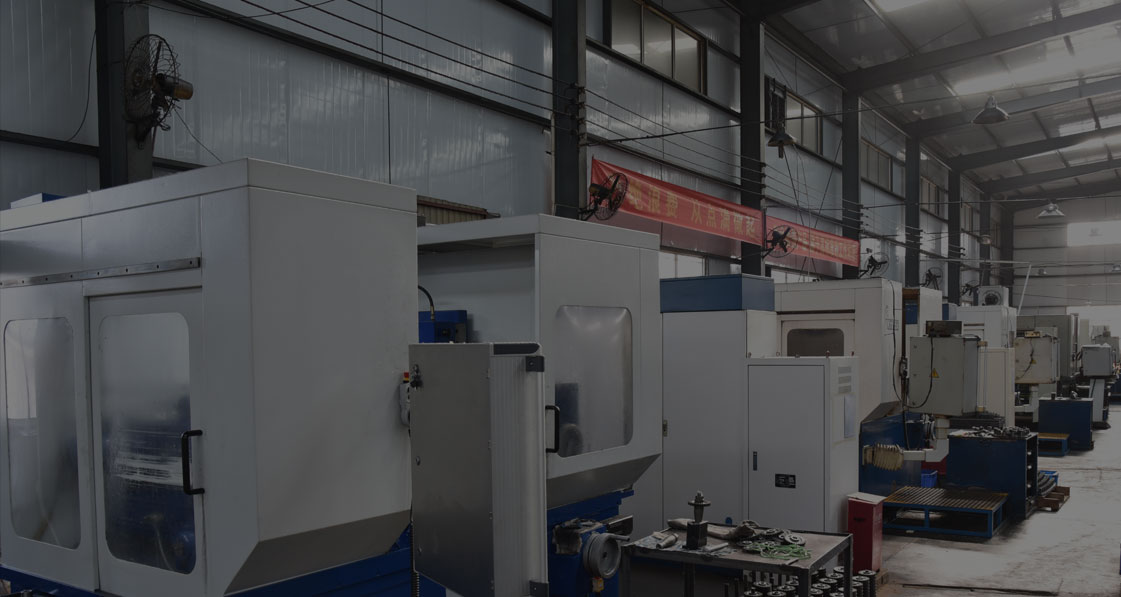

Witness our success

High-quality mechanical precision castings

Witness our success

Company Profile

With the wholesale supply, the customized price is affordable5 major product series

Registered capital

Sincere services

Honors

Upload the operating concepts of "pragmatism and innovation, honesty-based"News

With the wholesale supply, the customized price is affordable